It is critical to fix this sag because the ability of the roof to withstand its original load is compromised. In many old homes, rafters are undersized – using 2×6 or even 2×4 rafters. There are many instances where a rafter can – and should – be sistered: Imagine a splint on a broken arm – that’s the idea of a sistered rafter. Sistering a rafter is highly effective if done properly.

The length and type of sistering material can vary for many reasons, but the idea is to reinforce the bad rafter with a new, stronger rafter fastened flush. Sistering this type of rafter would require the use of 2×8 material placed flush against the existing rafter.

In new construction, roof rafters are 2×8 or greater. In this article, we are covering sistering a roof rafter. The purpose is to reinforce that framing member in the event of deterioration or failure. The term “sistering” means to attach a similar or identical sized piece of construction material – usually wood, steel, or engineered wood – to an existing framing member in a structure. What Does Sistering Mean In Construction?

RAFTER TAIL HOW TO

RAFTER TAIL PLUS

Glue the new rafter flush against the existing rafter, then use 16d nails plus a carriage bolt every 16” to affix the sistered rafter. The length of the sistered rafter should extend at least 3’ past the problem area on the existing rafter, on both sides. To sister roof rafters, you should use the same sized lumber as the rafter.

RAFTER TAIL INSTALL

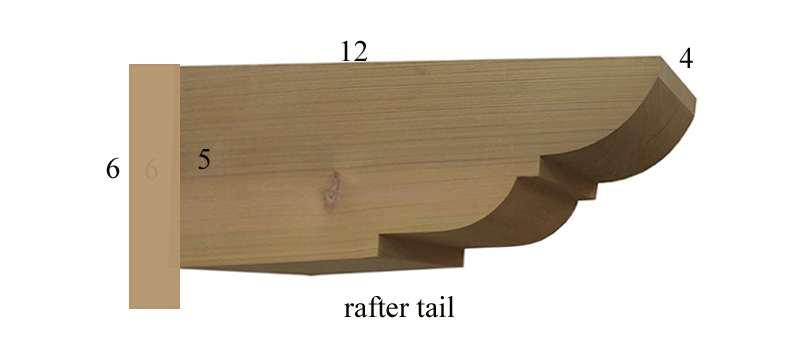

Our solution was to install new rafters next to the old ones, but at the time we weren’t quite sure how to sister roof rafters. When we went up to the attic, it was clear some of the rafters were in rough shape. Rafters Tails can be made any size, contact us for a quote.A while back, a relative of mine called me about a roof issue he was having – his roof was sagging and he thought he needed to fix some of his roof rafters. You may choose from any of our Rafter Tail Profile Cuts like Spartan, Napa, Craftsman, or Custom.

We offer PVC Purlins for longer rafter tails for addition support.Ĭhoose either a smooth or wood textured finish. They can be easily and securely mounted with no visible hardware to fasteners showing. Installation Tip: The rafter tails come hollow to be inserted on a custom made to fit PVC cleat (see image). PVC is the ideal weather resistant material for Pergola Rafters. Does not require painting for protection, but easily accepts paint to suit your color pallet. All four sides of the rafters end up perfectly smooth with no open pours.Īvailable with either a smooth or wood textured finish.Īs they are made from cellular PVC, thay can be cut, shaped, fastened and finished using standard carpentry tools. Our rafters do not require painting as we make them by folding and laminating four panels of ¾" PVC. Napa Pergola Rafter Tail - made with cellalar PVC in various sizes. Pergola Components |Rafter | Elite Trimworks I Elite Trimworks

0 kommentar(er)

0 kommentar(er)